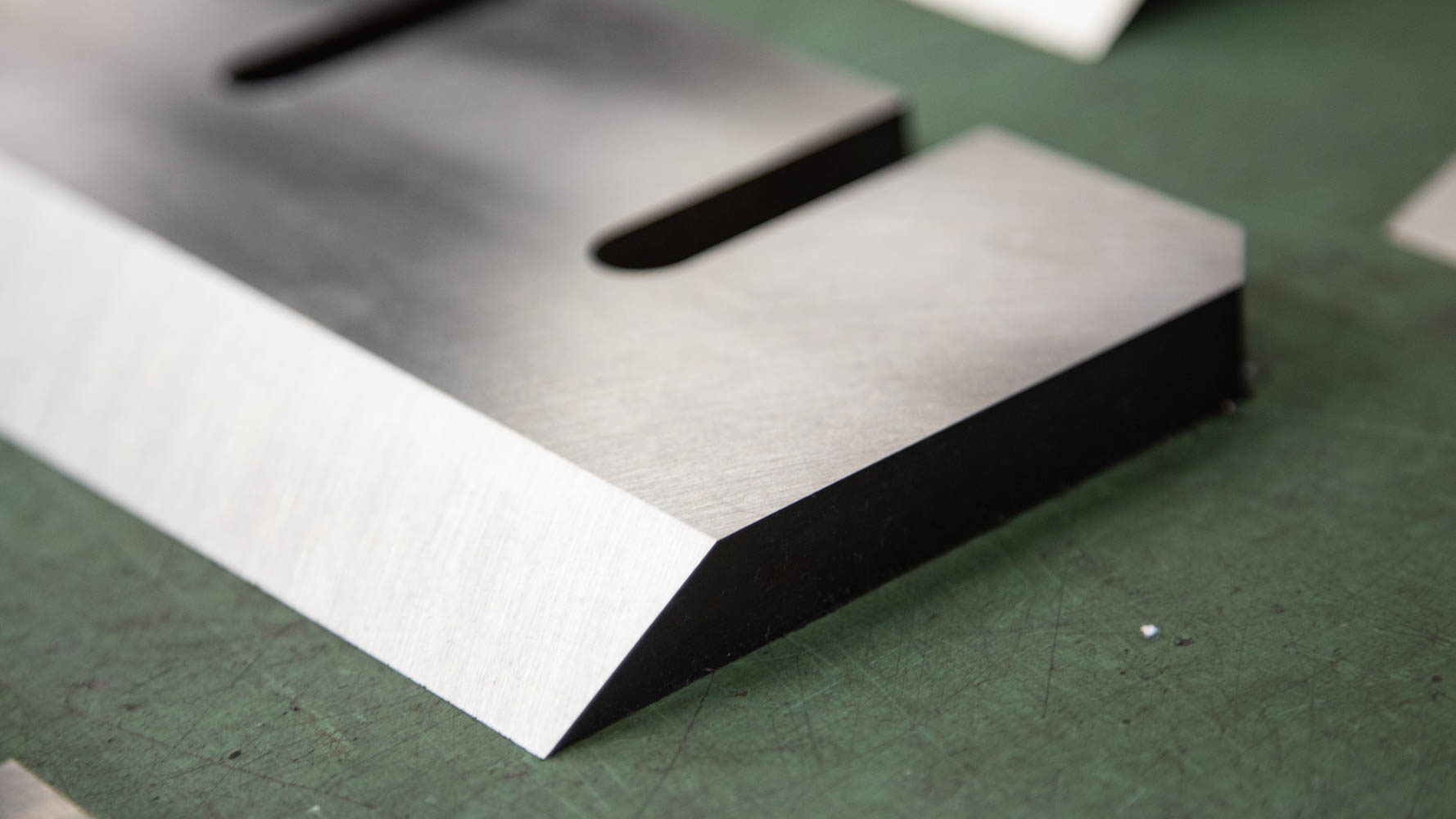

About our company

Röös Mekaniska is a company with extensive knowledge in milling and grinding. We are manufacturing knives for the wood industry from scratch. The fact that we are responsible for the entire production chain means that we have full control and can maintain the highest possible quality of our products. In addition to the knives, also a large number of other types of parts are manufactured for other industries. Our multi-operation machines in different sizes together with drawing and programming skills mean that we have great potential.